“We are all going to be surprised by the incredible number of places that 3D printing fits into both medicine and medically-oriented research.”

-Dr David H. Frakes, Principal Investigator

Image Processing Applications Laboratory, Arizona State University

How can biomedical researchers create better models to study the human body and analyze complex vessels and structures? How can doctors and physicians better visualize a patient’s anatomy before they ever operate on that patient? How can they make flat 2D images come to life in the physical 3D world? How can 3D-enabled biomedical research be applied directly with hospitals?

ASU Advanced Biomedical Research Case Study

The numbers are stark: Cerebral aneurysms affect 1 in 50 people and contribute to nearly 20,000 deaths in the USA alone every year. If an aneurysmal sac ruptures in the brain it becomes a highly lethal condition with a 50% mortality rate per rupture.

Arizona State University hosts one of the leading programs in cerebral aneurysm biomedical research with funding provide in part by the Mayo Clinic and National Science Foundation, among others. ASU’s research findings are directly applied at participating hospital partners and in the design of improved endovascular medical devices.

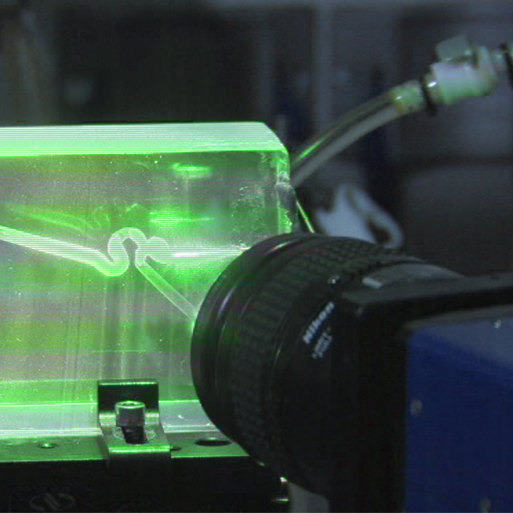

“The Solidscape machine is the heart, backbone of our process. We use that to build the core blood vessel models that we then translate into transparent flow models for our experiments,” according to Dr. David Frakes.

“The end product of our physical 3D modeling stage is a transparent block wherein there is a lost-core or a hollow portion of the model that is an exact replica of a cerebral aneurysm from a person. Rapid prototyping is how we get that first positive, before we get the negative, which is the flow model,” explains Dr. Frakes.

“All of the ground-truth data that is informing our simulations in the end, it comes from these models that the Solidscape machine helps us build.”